Standard APPs support the machine operator during preparation, optimization and systematic processing of production orders. This also simplifies, standardizes and automates machine operation. CELOS APPs enable end-to-end administration, documentation and visualization of order, process and machine data. CELOS offers a standardized user interface for all new high-tech DMG MORI machines.

#Dmg dmu 100 full#

The data is reliably migrated and all functions supported by the PLC will then be available to the full extent.ĭMU 50 – Optimal ease of use.

#Dmg dmu 100 update#

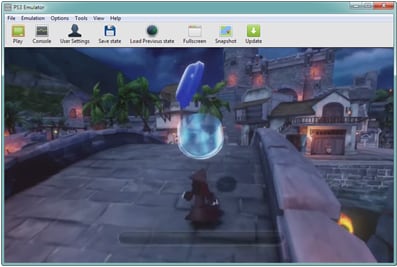

Future-proof Simple PLC-independent CELOS update to the latest version from every existing version. Regular and automated reports boost transparency in production. With the DMG MORI MESSENGER all status information of the linked machines and devices is available at a glance. Integration of any external program and web contents. Open Direct data import from MES and ERP systems. End-to-end End-to-end administration, documentation and visualization of order, process and machine data. CELOS ON THE ERGOline CONTROL WITH 21.5″ MULTI-TOUCH SCREEN Standardized Measurable Simple machine operation for all new high-tech machines made by DMG MORI. 0808 SMARTkey Personalized authorization of the operator: Individually adapted access rights to the control system and the machine. 02 1: Hydraulic component / motorsport 2: Milling head / tool manufacture 1 2Īpplications and Parts Machine and Technology Control Technology Technical Data APP MENU Like on a smart phone, the operator has direct access to all available applications through the APP MENU. With the DMU 50 DMG MORI offers the ideal, cost-effective entry into the world of 5-sided and even5-axis simultaneous machining.

The latest control technology with ERGOline Control with a 21.5″ multi-touch screen and CELOS guarantees optimum user-friendliness, precision and reliability. The extensive cooling measures are unique in this machine class and enable maximum precision.

Rapid traverses of 42 m/min and a swivel speed of 30 rpm guarantee dynamic machining and up to 30 % shorter cutting cycles. The larger working area and swivel range of the B-axis extend the range of applications of the machine. The 3rd generation of the DMU 50 meets the requirements of 5-axis machining of the future and is characterised by innovative mechanical engineering technology. Ever since the DMU 50 has been developed more than 20 years ago, standards and requirements are steadily increasing.

Applications and Parts Machine and Technology Control Technology Technical Data DMU 50 Compact universal machining centre of the 3rd generation for 5-axis simultaneous machining.

0 kommentar(er)

0 kommentar(er)